Every Machine Has a Heartbeat.

We Speak Its Language.

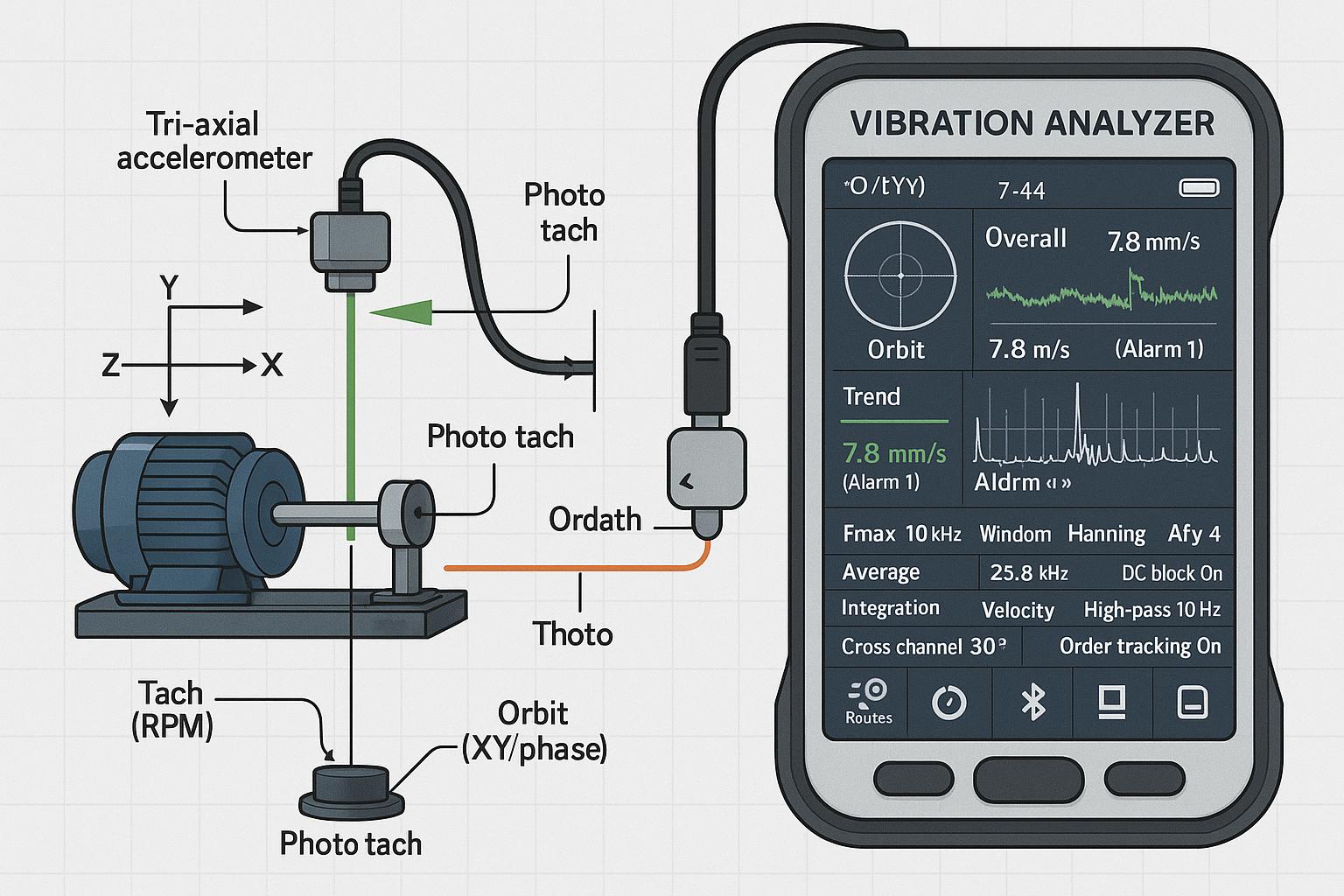

Our advanced vibrational analysis services translate the unique vibration signature of your machinery into actionable intelligence, allowing us to pinpoint developing faults with incredible accuracy long before they become catastrophic failures.

What We DetectDiagnosing the Root Cause of Failure

Vibrational analysis is the most powerful tool for diagnosing the health of rotating equipment. Each mechanical fault generates a unique frequency, allowing our analysts to identify the exact problem.

Imbalance

A "heavy spot" on a rotating component creates a powerful destructive force. We can detect imbalance in rotors, fans, and shafts, guiding precision balancing to restore smooth operation.

Misalignment

Vibration analysis is a key tool for confirming misalignment, identifying the specific type (angular or parallel), and verifying the success of corrective laser alignment.

Bearing Defects

We can identify specific faults in rolling-element bearings—such as defects on the inner race, outer race, or rolling elements—providing a clear picture of bearing health.

Gear Wear & Damage

The interaction of gear teeth creates a distinct vibration pattern. We analyze this "gear mesh" frequency to detect issues like wear, eccentricity, and broken teeth before they lead to gearbox failure.

The Strategic Value of Vibrational Analysis

A consistent vibration monitoring program is the cornerstone of any modern reliability strategy.

Prevent Catastrophic Failures

This is the single most effective technology for predicting and preventing major machinery breakdowns, saving millions in potential equipment loss and production downtime.

Optimize Maintenance Schedules

Move from reactive or calendar-based maintenance to a truly condition-based approach. Repair and replace components only when the data shows it's necessary.

Increase Asset Lifespan

By identifying and correcting root causes of failure like imbalance and misalignment, you dramatically extend the operational life of your most valuable assets.

Improve Root Cause Analysis

When a failure does occur, historical vibration data is invaluable for understanding the sequence of events, allowing you to prevent a recurrence.

Expert Analysis, Actionable Reports

Our greatest asset is our team of certified vibration analysts. Technology collects the data, but it takes years of experience to interpret the complex spectral readings and provide a clear, accurate diagnosis. Our process is built on this expertise.

- **Baseline Data Collection:** We establish a baseline vibration signature for your critical machinery.

- **Routine Monitoring:** We collect data on a scheduled basis to trend the health of your equipment over time.

- **Advanced Analysis:** Our ISO-certified analysts interpret the spectral and waveform data to diagnose specific faults.

- **Clear Recommendations:** You receive a report that is free of jargon, clearly stating the identified fault, its severity, and our recommended course of action.

Schedule a Vibrational Analysis Consultation

Take the first step towards a world-class reliability program. Contact our team to discuss your equipment and monitoring needs.